To customers who manufacture copper products in-house for control panels and distribution boards.

We assist in reducing labor hours and costs through the outsourcing of copper processing.

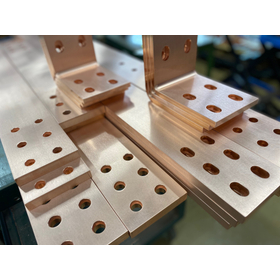

Eishin International supports your manufacturing with copper processing. ■Features■ Utilizing a network derived from trading companies, we directly import copper materials from overseas (domestic materials can also be procured). To meet the demands of domestic customers for copper processing and to enhance service with shorter delivery times, we process at two domestic locations (Osaka Prefecture and Aichi Prefecture) within the Eishin Group. We have introduced the latest dedicated machines for copper busbar processing from Germany and promote digital transformation (DX) to address the shortage of personnel in the industry and among customers. We handle everything from mass-produced items for power distribution equipment to custom-made products, as well as tin, nickel, and other plating treatments. Our company provides comprehensive services for electrical copper in the power distribution industry and offers a one-stop solution for management through the outsourcing of copper bar processing! ■Benefits of Outsourcing Copper Bar Processing■ 1. Liberation from material procurement, storage, and financial management. 2. Ability to perform processing that cannot be done with in-house equipment, eliminating the need for plating treatment. 3. Savings in processing time, resolution of personnel shortages, and freedom from processing errors. As a result, we can allocate personnel to assembly wiring and inspection, thereby improving productivity.

- Company:エイシンインターナショナル

- Price:Other